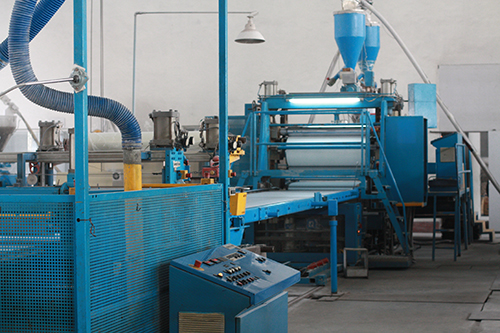

Makebest specialize in rigid foam PVC extrusion. We own 8 production lines. 5 production lines are imported from Breyer-Germany,Covema-Italy and others are domestic ones .Various products can meet different application and market.PVC free foam sheet, PVC crust foam sheet , PVC Celuka foam sheet , PVC foam profile all can be supplied. We also develop PP hollow sheet, ABS double color sheet as supplement.

PVC Foam Sheet is U-PVC chemically foamed, rigid, light weight extruded sheet with fine & homogenous closed cell structure, and is manufactured to be used for interior and limited exterior application .

FEATURE :

● Light weight but strong, rigidity

● Good mechanical performance

●Can be print, painted, film covered, etc

●Can be heat formed and welded

●Excellent chemical resistance, good resistance to light & weathering

●Water proof, mould proof, rot proof

● Heat and sound insulation

● Self-extinguish

●Easy to clean and maintain

● Long performance life

●Environmental friendly

It is a perfect replacement for wood. It can be worked easily and quickly with traditional wood and metal tool, but will not warp, swell or decay in wet area.

APPLICATION:

Due to the advantage of its distinct impact and chemical resistance, PVC foam sheet is widely used in our daily life including the followings:

Advertising :

Signage

Display (POP, POS etc.)

Exhibition stands

Photograph backing

Construction:

Partition and wall cladding (internal and external)

False ceiling

Paneling

Interior design

Furniture: kitchen & bathroom cabinet, shelving, slat wall panel and shop counter

Lining structures for corrosive and moisture environment.

Internal decoration or cabinets making for automobile, railway, metro and vessel.

Concrete formwork

Windows or doors manufacture

Shopfitting

Others :

Model making

Packing material and containers

Protection shell for machinery

PROCESSING

You can perform with usual wood and metal equipments and tools:

Deeping drawing

Milling

Drilling

Varnishing

Bolting

Welding

Embossing

Punching

Riveting

Backing, laminating

Water-jet cutting

Coating

Sawing

Nailing

Screwing

Thermoforming

Gluing

Lacquering

Printing

Flocking

Die-cutting

Engraving

Cutting